Helping advanced manufacturing gain competitive advantage

The ability to manufacture products and components ‘right first time, right every time' is key to reducing costs and gaining competitiveness. NPL's Product Verification Programme (PVP) helps companies to manufacture products to original design specifications through better measurement and inspection practices.  We look at every aspect of your measurement practices and procedures and find the improvements that will make a difference. Also, as a public organisation, NPL is truly impartial and has no affiliation with any specific manufacturers or suppliers. We can therefore offer independent advice, training, consultation and dispute resolution services.

We look at every aspect of your measurement practices and procedures and find the improvements that will make a difference. Also, as a public organisation, NPL is truly impartial and has no affiliation with any specific manufacturers or suppliers. We can therefore offer independent advice, training, consultation and dispute resolution services.

How does it work?

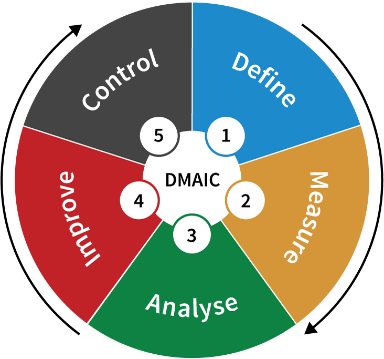

If you have a specific manufacturing problem, we can work with you to understand and define the problem. We then set out a programme of development with suitable tools, often using a Six Sigma, DMAIC (Define, Measure, Analyse, Improve and Control) framework approach.

Alternatively, NPL’s specialist team can come to your site and spend time getting under the skin of your manufacturing and inspection practices and procedures. We then produce a diagnostic report that details areas for improvement.

Our recommendations have specific modules to address the gap between current status and best practices. The diagnostic report and recommendations can include savings that can be expected including Return on Investment information.

Product verification healthcheck – understand where you are

- Dedicated time on site by NPL practitioner(s)

- Review all aspects of ‘measurement’ or targeted at specific focus areas

- Full diagnostic report generated, detailing areas of good and bad practice

- Recommendations of modules required to close gaps, with expected impact

Module 1: Managing the product verification process

This module addresses how measurement is tackled by the organisation, looking at the implications of addressing the measurement aspect of a process at the correct time to maximise potential. It is aimed at the organisation’s leaders.

- Managing measurement: approaches and decisions for managers

- Managing calibration: approaches and decisions for managers

- Managing variation: approaches and decisions for managers

- Defining and planning Measurement & Inspection (M&I) skills/system

- Developing QMS

Module 2: Measurement and inspection foundation tools

This module provide staff with the ability to understand and apply techniques to quantify the capability and understand the behaviour of measurement processes. They provide the foundation stones of good measurement practice.

- Measurement system analysis / Evaluating measurement process – basic training, tools and techniques

- Shop floor metrology

- Equipment calibration – good practice and application

- Environmental considerations for measurements

- Machine tool verification

- Data design and problem solving

Module 3: In-process validation and inspection

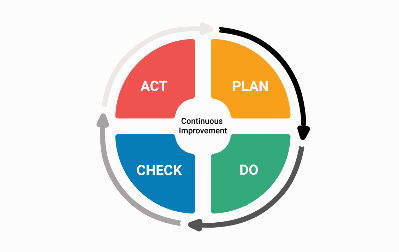

This module builds on the foundations to move to a more advanced approach to measurement. It helps shift from ‘goal-keeping’ culture to data driven continuous process control.

- Application of on-machine probes

- Operator-led inspection

- Statistical process control

- Validation and inspection prevention

Module 4: Application of technology and innovation

This module has focused training for Coordinate Measuring Machines (CMM) related measurement and for specific measurement of temperature, electrical and pressure.

- CMM good practice

- CMM – artefact good practice and implementation

- Other measurement technologies on request, such as laser tracers or portable articulated arms

Module 5: Part/process specific projects

This module covers good practice for measurement in line with structured approaches such as 6 Sigma DMAIC. It will cover the impact of the measurement aspect of the full process.

- Manufacturing compatibility and process audits

- Quality costs analysis – tools, techniques and application

- Design of experiment – tools, techniques and application

- D/PFMEA – tools, techniques and application

Module 6: Compliance with industry standards

This module covers specific processes required to ensure compliance with industry standards.

ISO 10012 – Measurement Management Systems

ISO 17025 – General requirements for the competence of Testing and Calibration Laboratories

NADCAP – National Aerospace and Defense Contractors Accreditation Program

- NADCAP M&I gap analysis

- ISO 17025 / ISO 10012 gap analysis

- AS9100:2016 gap analysis

- AS9100:2016 awareness and auditor training

Sharing in Growth (SiG) programme

NPL has been awarded a second contract with the SiG programme to extends its work in supporting companies in the aerospace supply chain through its Product Verification Programme. The SiG programme supports UK aerospace companies to increase productivity and competitiveness in international markets. The intense four-year SiG training and development programme is focused on leadership, culture and operational excellence, delivered by SiG's team and experts, including a team from NPL which provides the skills, knowledge and training to manage, analyse and improve measurement and inspection processes.

Don’t see what you are looking for? Our diverse skill set enables us to provide bespoke solutions. Please contact us to discuss your requirements.