Our high accuracy roundness measurement service is primarily intended for the calibration of glass hemi-spheres used in the calibration of roundness measuring instruments. A novel error separation technique is used to separate the spindle error of the NPL instrument and the component error.

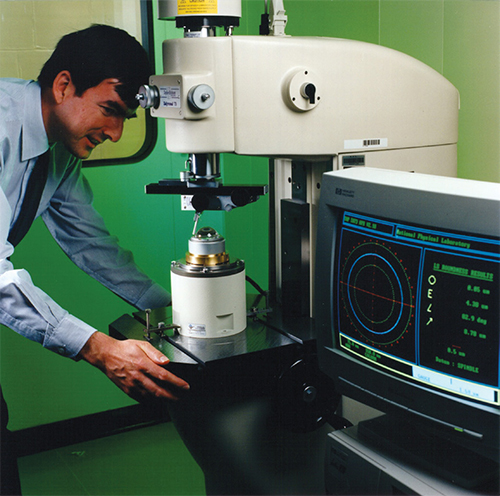

Roundness measurement facility

The NPL facility is based around a modified Talyrond 73 developed in collaboration with Taylor Hobson.

The fundamental basis of the instrument’s design is to use a spindle with a highly reproducible rotation and then use a novel error separation technique to significantly reduce the errors associated with the lack of perfection of the spindle geometry. The instrument used to make the measurements is capable of collecting 2000 data points per revolution.

In operation, the component to be measured is placed on a rotary stage and data collected at several orientations of the stage. The Fourier-series representations of the signal at every orientation are then calculated and these representations, along with an equivalent model in the frequency domain that relates the various Fourier representations, are solved to find the Fourier representations of the component and spindle errors.

Don’t see what you are looking for? Our diverse skill set enables us to provide bespoke solutions. Please contact us to discuss your requirements.

Our research and measurement solutions support innovation and product development. We work with companies to deliver business advantage and commercial success.

Contact our Customer Services team on +44 20 8943 7070