Making nanometre and sub-nanometre displacement measurements

Multi-axis traceable displacement measurement is becoming increasingly important in nanotechnology and nanometrology. Optical interferometry is the most widely used tool for making traceable displacement measurement at the nanometre level both in metrology laboratories and in nano-manufacturing and characterisation.

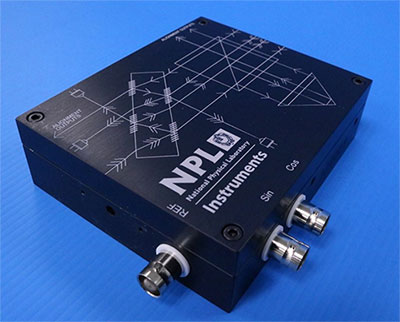

We have developed several interferometers and fringe counting systems for high accuracy displacement measurement for both applications within NPL and externally. Applications include stage metrology and atomic force microscopy metrology.

We are also investigating measurement of the errors associated with high precision scanning stages used both in metrological atomic force microscopes and in general in nanopositioning applications. A suite of algorithms is being developed for the characterisation of stages using calibration gratings.

X-ray interferometry

An X-ray interferometer can be thought of as a ruler or translation stage. The graduations or steps are equal to the spacing between planes in a crystal, from which X-rays have been diffracted, in this case the silicon planes with a spacing of 192 pm. The X-ray interferometer provides a route to traceability at the nanometre and sub-nanometre level without the need for fringe interpolation (resolving less than one interference fringe) which is a limiting feature of optical interferometry.

NPL has provided traceable length scale measurements at sub-nanometre levels using X-ray interferometry for several European projects and most recently championed the uptake of X-ray interferometry and use of the silicon lattice parameter in the 2018 update of the mise en pratique for the metre.

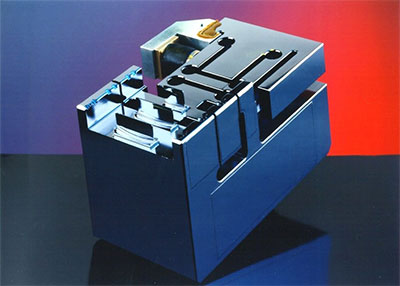

Metrological atomic force microscopy

The atomic force microscope can be regarded as the window into the nanoworld with applications in imaging, metrology and manipulation. A metrological atomic force microscope has traceable metrology, usually optical interferometry that measures the displacement between the atomic force microscope tip and the sample. A metrological atomic force microscope can be used to calibrate step height standards with nanometre uncertainty and lateral pitch standards with sub nanometre uncertainty. Currently, a number of new designs for the head for the metrological atomic force microscope are under way to produce a suite of versatile heads that can be used both for calibration of transfer artefacts and measurement of irregular surfaces.

We are also investigating intelligent data scanning methods for atomic force microscopy. NPL and the Czech Metrology Institute (CMI) have jointly written a series of intelligent scanning routines (Gwyscan) to provide alternative scan trajectories, selective scanning, drift compensation and edge detection. This will increase the versatility of metrological atomic force microscopes.

We are also investigating intelligent data scanning methods for atomic force microscopy. NPL and the Czech Metrology Institute (CMI) have jointly written a series of intelligent scanning routines (Gwyscan) to provide alternative scan trajectories, selective scanning, drift compensation and edge detection. This will increase the versatility of metrological atomic force microscopes.

In collaboration with University of Bristol, we have brought metrology to high speed atomic force microscopy and turned the technique from a qualitative imaging technique into a quantitative imaging technique.

Find out more about NPL's Dimensional measurement and inspection of components services

Find out more about NPL's High accuracy micro coordinate measuring machine services

Contact us