.jpg)

By Max Ryadnov, NPL Fellow (Engineering Biology)

On 3 November, the UK took a significant step forward in engineering biology with the official opening of the UK Reference Biofoundry at the National Physical Laboratory (NPL). The facility was opened by Lord Vallance, Minister for Science, Innovation, Research and Nuclear, marking a milestone in the nation’s capability to support innovation and scale in this transformative field.

Engineering biology is one of the six frontier technologies identified in the UK’s modern industrial strategy, alongside AI, quantum, semiconductors, cyber security, and advanced connectivity. These technologies are expected to drive future growth, strengthen national security, and enhance economic sovereignty.

Among them, engineering biology stands out for its potential to revolutionise industries from healthcare and agriculture to materials and energy by enabling breakthroughs such as converting waste into sustainable chemicals, developing new materials, and addressing global food security.

As Lord Vallance emphasised, metrology and standards will become increasingly vital as industries move toward biological production as a defining characteristic.

Without robust measurement and traceability, innovation risks stalling before it reaches the market. The UK Reference Biofoundry addresses this gap by providing the metrology and standards infrastructure that engineering biology desperately needs to scale confidently.

By embedding measurement and traceability at the heart of engineering biology, NPL will ensure that the outputs of this field are not only ground-breaking, but reliable, safe and fit for purpose. That’s how we turn innovation into impact.

Lord Vallance

The NPL biofoundry is application-agnostic, designed to serve diverse sectors across industry. Its capabilities are evolving to support existing and emerging industry needs and include:

By embedding measurement science at the heart of engineering biology, the facility enables innovators to turn ideas into impact – whether that’s in pharmaceuticals, sustainable chemicals, or advanced materials.

Government investment into engineering biology, from curiosity-driven research to mission hubs, reflects a clear commitment to this area in the UK. the UK Reference Biofoundry is that missing link for the critical role that standards and metrology play in innovation. Scaling engineering biology is challenging, but essential for translating research into products and services.

This facility positions the UK among a very select group globally – there is only one other comparable centre worldwide – giving British innovators a competitive edge in a rapidly evolving landscape.

Engineering biology is a recognised strategic enabler for sustainable growth. By investing in measurement and standards, the UK is laying the foundation for industries that will define the future. Industries that can convert waste into valuable resources, create resilient food systems, or develop next-generation materials.

The opening of the UK Reference Biofoundry is a milestone. It demonstrates how collaboration between government, science, and industry can unlock innovation and deliver impact at scale.

Learn more about NPL’s work in metrology for engineering biology and the UK Reference Biofoundry

By Dr Cyrus Larijani, Head of Quantum Programme

What a week Quantum Week 2025 was! Described by the Institute of Physics as a celebration of the UK’s leadership in quantum science and technology, it was nothing short of transformative. Across five days, the UK quantum community came together with global partners to share knowledge, forge collaborations, and showcase innovation.

For NPL, it was an opportunity to demonstrate our pivotal role in shaping the future of quantum technologies—both at home and internationally. As the UK’s National Metrology Institute, NPL kicked off Quantum Week with a clear message: metrology and standards are the bedrock of science and innovation. Just as a building relies on strong foundations, quantum technologies depend on trusted measurements and agreed standards to scale confidently from research to real-world deployment. This principle guided every conversation and collaboration throughout the week.

We were honoured to start Quantum Week with two major milestones. First, NPL hosted one of 11 global events marking the International Year of Quantum Science and Technology (IYQ), a UNESCO-led initiative commemorating 100 years since the foundations of quantum mechanics. This global celebration underscores the importance of quantum science in addressing future challenges and highlights the UK’s commitment to international collaboration.

Second, we officially launched NMI-Q, a G7-announced initiative bringing together National Metrology Institutes to accelerate quantum standardisation. The launch event featured a video reveal and remarks from Lord Vallance – Minister for Science, Innovation, Research and Nuclear – who emphasised the UK’s ambition to lead in quantum innovation. NMI-Q will ensure that as quantum technologies mature, they do so on a foundation of globally harmonised standards – critical for interoperability and trust.

Quantum technologies are moving rapidly from lab to market, redefining secure communications, precision sensing, and scalable computing. On Tuesday, NPL joined leaders from business, defence, and investment sectors at the Canadian High Commission for a strategic dialogue with Canada – one of the world’s leading quantum nations. The event showcased Canadian quantum innovators and explored opportunities for collaboration in communications, computing, and post-quantum cryptography. These discussions reinforced the importance of bilateral partnerships in accelerating quantum adoption and ensuring resilience in critical technologies.

Midweek saw a 20-person delegation from Colorado, organised by Elevate Quantum and the UK Foreign, Commonwealth and Development Office, visit NPL. We shared insights on quantum communications and computing and explored collaboration under the US–UK Technology Prosperity Deal. The day also featured the signing of an MOU between AIST and GQuat, strengthening collaboration on quantum research and standardisation.

Later, NPL representatives attended the NATO TQC Industry Network Reception organised by UK Quantum which also brought together academia, industry, and government leaders to strengthen the UK’s global quantum position.

It was also fantastic to attend the IOP Awards Dinner, celebrating companies that have worked closely with NPL and contributed to advancing quantum technologies in the UK. Seeing so many of NPL’s partners recognised for their achievements was a reminder of the collaborative spirit driving this technology area forward.

Thursday was all about deepening international ties. At the Japanese Embassy, discussions centred on optical lattice clocks, quantum metrology, and sensing technologies—critical areas for global standardisation. Later, NPL hosted a Korean delegation comprising government officials, industry leaders, and academics. The visit highlighted NPL’s role in quantum standardisation and scientific leadership and identified four key areas for future collaboration: Standardisation, Infrastructure, Skills, and Research. These conversations underscored the shared ambition to build interoperable quantum systems and a skilled workforce for the future.

The week culminated in the UK National Quantum Technologies Showcase, where NPL engaged with innovators and industry leaders to discuss how our expertise in measurement science can accelerate quantum adoption. It was inspiring to see the breadth of applications—from secure networks to quantum computing—moving closer to real-world deployment. For NPL, the Showcase was an opportunity to demonstrate how trusted measurement underpins confidence in emerging technologies.

Quantum Week 2025 reinforced a simple truth—progress in quantum technologies depends on collaboration, trust, and standards. At NPL, we are committed to enabling this progress through world-class research, international partnerships, and leadership in quantum metrology.

Just as metrology has underpinned every scientific revolution, it will be the foundation for quantum innovation. As quantum moves from theory to application, NPL continues to play a key role in the UK’s quantum programme and we will be the backbone of confidence in this transformative, enabling technology.

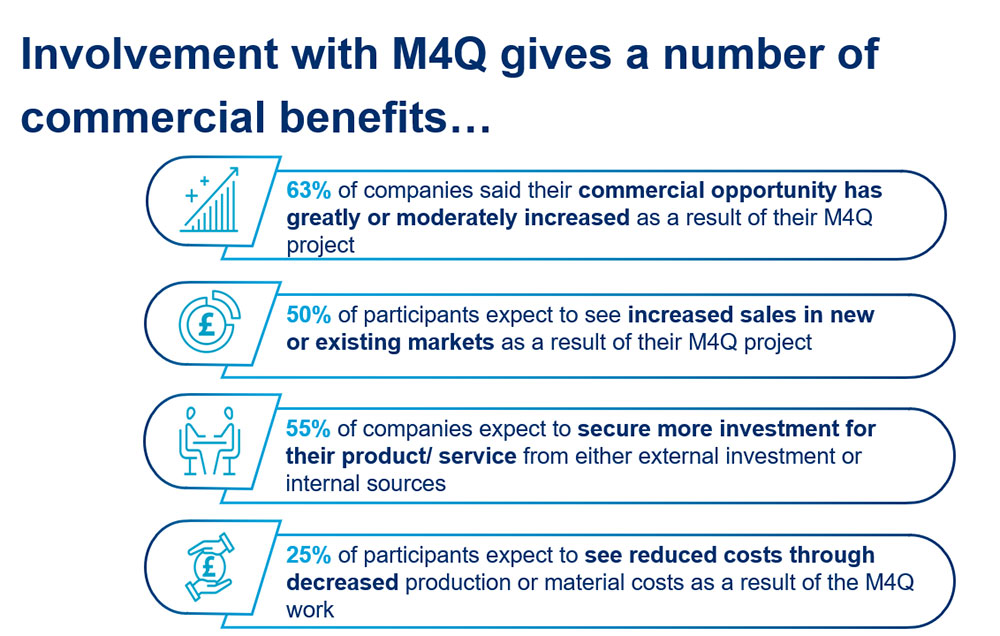

The National Physical Laboratory’s Measurement for Quantum (M4Q) programme is designed to support the growth of quantum technology businesses, helping to bridge the critical gap between research prototypes and market-ready solutions. By providing 20 days access to NPL’s experts at no cost*, we empower business through tailored measurement and calibration support to refine their products, reduce costs and accelerate their route to commercialisation.

Read on to find out about two success stories from our recent collaborations in the quantum space.

INEX, the UK’s leading full-service compound semi-conductor development and fabrication company, specialises in the production of vapour cells for ultra-accurate atomic clocks.

Through our work with INEX, we ensured their product met specifications for gas composition, pressure, and temperature by providing detailed modelling and radio-frequency spectroscopy to calibrate and characterise cells.

Our collaboration paid off, and with metrology data provided by NPL, INEX was able to develop a quality control device which reduced their manufacturing costs by 20%. We were also able to refine their vapour cell design, expanding marketing opportunities by improving their product’s functionality.

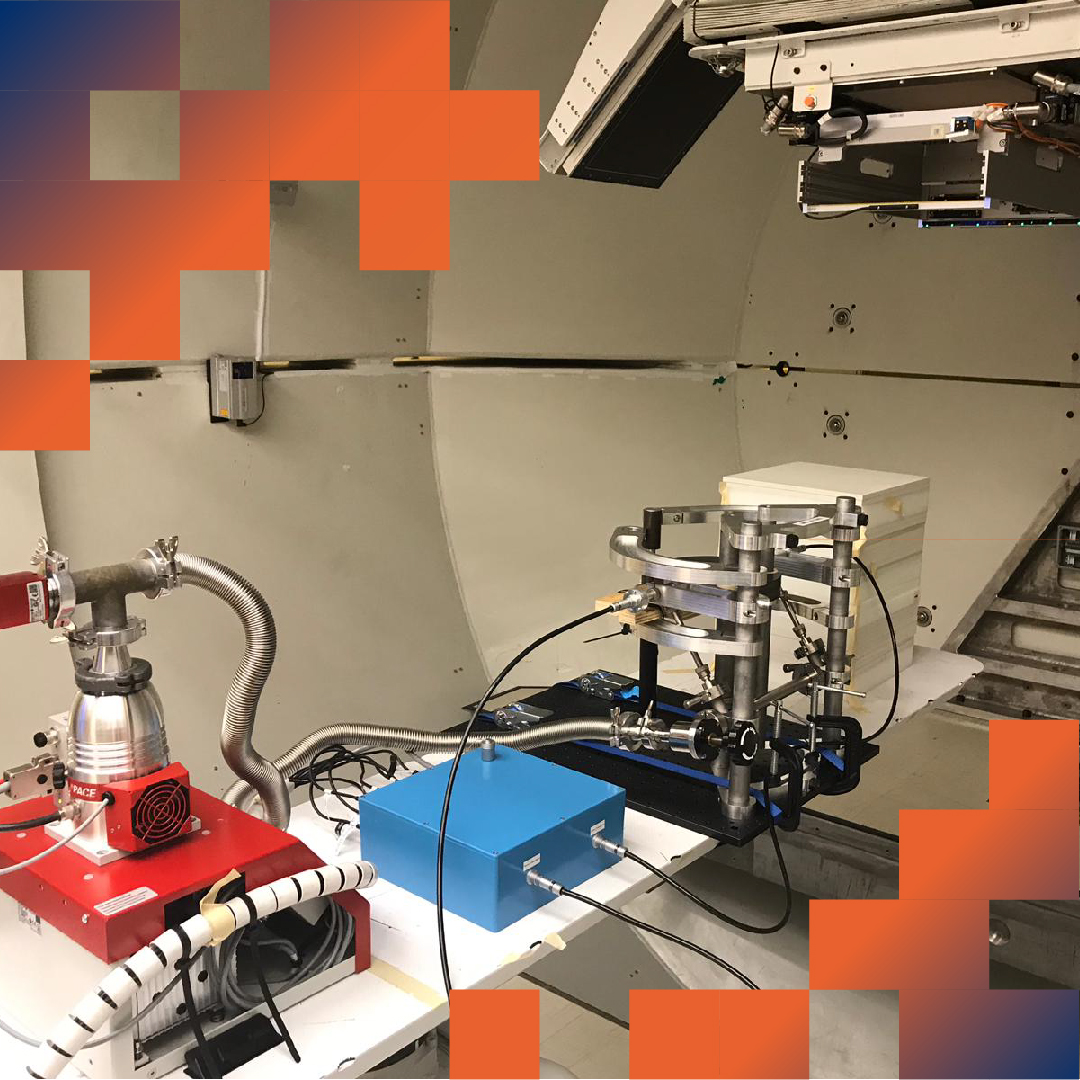

Another success story from the M4Q programme is our collaboration with QLM, a company that approached us with the challenge of developing a portable system for visualising greenhouse gas emissions.

We were able to provide novel optical measurement techniques and calibration tools to give QLM a deeper understanding of their laser systems physics and functionality, resulting in the creation of a calibration rig.

By improving manufacturing processes and reducing production costs, QLM was able to position itself as a scalable and affordable solution to emissions monitoring, strengthening its competitive advantage in the market.

Without NPL’s expertise and access to the full range of cutting-edge measurement options, this important work may not have gone ahead, or succeeded.

Xiao Ai - Co-founder and CTO at QLM Technology

Through our M4Q programme, NPL is committed to nurturing the quantum technology industry, helping companies like INEX and QLM to unlock new capabilities, reduce costs and bring innovative products to market. To explore how your business could benefit from quantum measurement and testing support,

*Eligibility criteria apply.

NPL, in collaboration with London Biofoundry and BiologIC Technologies Ltd, released an analysis on existing and emerging DNA synthesis technologies in Nature Reviews Chemistry, featuring the work on the front cover.

The study, which was initiated by DSTL, set out to understand the development trajectory of DNA synthesis as a major industry drive for the UK economy over the next ten years. The demand for synthetic DNA is growing exponentially. However, our ability to make or write DNA lags behind our ability to sequence or read it.

The study reviewed existing and emerging DNA synthesis technologies developed to close this gene writing gap.

DNA provides a universal tool to engineer and manipulate living systems. Recent progress in DNA synthesis has brought up limitless possibilities in a variety of industry sectors. Engineering biology, therapy and diagnostics, data storage, defence and nanotechnology are all set for unprecedented breakthroughs if DNA can be provided at scale and low cost.

As an example, DNA has already been used to write books, episodes of Netflix series, video games and is being applied to catalogue the entire British Library. Just one gram of DNA is estimated to store over 17 Exabytes of information, whereas five exabytes is all that is needed to store all the words spoken by mankind.

The development of robust metrology and suitable standards are required to accelerate and safeguard the uptake of synthetic DNA by the end users. NPL supports this endeavour by developing a toolbox of traceable reference materials, methods and standards, which will underpin further developments in the field.

Supporting commissioning of new radiotherapy equipment safely and promptly

New low-cost flexible X-ray detectors

Characterising hydrogels for cancer treatment

NPL scientists have worked on a range of projects that are set to significantly improve the accuracy of a type of radiotherapy treatment called proton beam radiotherapy. The benefits of this therapy include more precise targeting of cancer tumours without damaging surrounding healthy tissue. It massively minimises the unpleasant side effects of radiotherapy, particularly in the case of paediatric patients, including cardiac failure, pulmonary fibrosis, and secondary cancers.

Proton beam radiotherapy is seen as a superior option to established forms of radiotherapy because the radiation can be confined largely to the tumour, minimising the damage to surrounding healthy tissue. But in order to make the most of the treatment, the accuracy of the radiation dose from proton beam treatment must be similar to that achieved using existing radiotherapy treatments.

To achieve this aim, the team at NPL made three important breakthroughs:

We are excited to see these developments make an impact for patients and clinicians.

Ana Lourenço, Principal Scientist in Medical Radiation Science, presented her research work on the development of the world's first primary standard for proton radiotherapy beams. Prior to this work, globally, there was no dedicated calibration service for proton beams based directly on a primary standard resulting in higher than desired uncertainties on the dose delivered to cancer patients.

Ana Lourenço, Principal Scientist in Medical Radiation Science, presented her research work on the development of the world's first primary standard for proton radiotherapy beams. Prior to this work, globally, there was no dedicated calibration service for proton beams based directly on a primary standard resulting in higher than desired uncertainties on the dose delivered to cancer patients.

“Our team at NPL are widely recognised as world leaders in areas of proton dosimetry. We have worked to develop a deeper understanding of fundamental aspects of dosimetry for this type of beam which has culminated in us developing dedicated primary standard specifically for proton radiotherapy. We are able to further refine the understanding of the response of ionisation chambers used in the clinic. Combined with that, my team have developed protocols for auditing clinics - a vital aspect in ensuring patient treatments are optimally delivered, and have developed our own materials specifically to mimic the response of tissue, bone etc in the proton beam. It is a privilege for me to lead such a dedicated and talented team of scientists whose work has a real impact in helping to improve outcomes and the quality of life of cancer patients.” - Science Area Leader, Russell Thomas

At the National Physical Laboratory (NPL), we’re working to understand the make-up of cancer tumours, locate and quantify nuclear materials, and investigate advanced materials.

Mass spectrometry imaging (MSI) provides powerful eyes on the molecular and atomic world. It’s a tool that applies to all research fields, allowing us to amass huge amounts of detail about biological, materials and agricultural samples.

NPL is developing world-leading mass spectrometry technologies and the standards for best practice that can be rolled out across the world. We are also developing and applying the latest machine learning techniques to visualise and interpret mass spectrometry data.

Over the past decade, the National Centre of Excellence in Mass Spectrometry Imaging (NiCE-MSI), based at NPL, has worked on numerous high-impact projects, from taking part in cancer research, to supporting the development of improved antibiotics to beat resistant bacteria.

The centre began with just a handful of scientists that has now grown to a multidisciplinary team of 30, working with state-of-the-art imaging techniques, including secondary ion mass spectrometry (SIMS) and Matrix-assisted laser desorption ionisation (MALDI). These capabilities are bringing confidence to users in pharmaceutical sciences, biological sciences and semiconductors.

In the next decade, the team aim to drive the use of these techniques from solely a research environment to routine practice in industry and the NHS. The team are constantly improving the resolution and broadening the applications for MSI which could lead to reduced failures, cost savings and helping to meet regulatory requirements.

How the NanoSIMS capability is supporting pharmaceutical innovation

Every day, we work closely with leaders in UK industry to provide them with expert measurement services. Our customers trust us to deliver measurements that are accurate, traceable, and assured to a degree of certainty underpinned by our world-leading science.

Below is just some of the feedback we have received from our customers on the measurement work we have conducted for them, making it possible for them to bring innovative products and services to market with confidence and assured data.

NPL’s impact is monumental as the main provider of the UK’s measurement standards, which is something that shouldn’t be taken for granted. NPL takes the time to worry about the quality and assurance of standards so that the public doesn’t have to.

Hexagon Metrology Ltd

Our work with NPL delivered significant impact during a critical stage of company growth.

Inductosense

As a result of participation in a research programme with NPL we were able to more accurately assess the risks in our manufacturing process, components and product designs. We were able to prove the relatively low risk of problems using existing materials and potentially costly search for, and implementation, of alternatives. The impact of working with NPL was both time and cost savings. Working with NPL was like having insurance in place, providing confidence in process and designs and creating standards and specifications against which later products and components could be designed.

Steve Kuc, SSTL

In addition to our standard commercial measurement offering, we run a number of programmes which offer measurement services at no cost for a fixed time period in specific industries and geographies. Our Measurement for Business (M4B) programme is one such example and is currently open for applications.

Our research and measurement solutions support innovation and product development. We work with companies to deliver business advantage and commercial success.

Contact our Customer Services team on +44 20 8943 7070