.png?lang=en-US) The world of manufacturing is rapidly evolving, with the increased need for automation and digital transformation. Manufacturing companies require their future manufacturing practices to be highly accurate, traceable, and have flexible measurement systems that increase productivity and inherently add value to the manufacturing process.

The world of manufacturing is rapidly evolving, with the increased need for automation and digital transformation. Manufacturing companies require their future manufacturing practices to be highly accurate, traceable, and have flexible measurement systems that increase productivity and inherently add value to the manufacturing process.

We have developed and patented an innovative coordinate measurement system to address this need. It is a new class of measurement system that enables the next generation of automated manufacturing applications, like measurement-assisted automation, machining and assembly. It will be one of the first commercial instruments to incorporate digital measurement traceability to the international system of measurement (SI) on the factory floor.

For more information, please contact us.

Customers of NPL’s dimensional measurement services repeatedly asked three questions about existing measurement equipment in the market: “are the results right?”, “is it in calibration?” and “what is the actual measurement accuracy?”

These questions helped us identify that current industrial coordinate measurement systems do not fully meet the needs of manufacturers. Existing laser trackers measure targets sequentially, limiting applications and increasing measurement times and require skilled staff to operate them. They also require expensive calibration processes, regular field checks, and lack real-time performance indicators. While photogrammetry measures targets simultaneously at the expense of accuracy. Both require an external reference for traceability. Neither provide measurement-specific uncertainty estimations and although photogrammetry could, it’s not always implemented. This results in lost and extended production time, increased expense and reduced competitiveness.

The challenges also vary across different industries, each with specific coordinate metrology requirements.

Advanced Manufacturing needs a ‘right first-time’ or zero-defects approach, ideally using automation to have:

Digital Manufacturing requires confidence in data through measurement-specific uncertainty estimates which are traceable to the SI metre to have:

In Healthcare, new diagnostic and treatment systems, such as radiotherapy, require confidence in accurate and reliable patient positioning for regulatory compliance and productivity, which needs to have:

To meet these challenges, metrology systems need to adapt to be more flexible, accurate, scalable, and accountable for the impact they have within manufacturing.

NPL’s new coordinate measurement system addresses these challenges across different sectors.

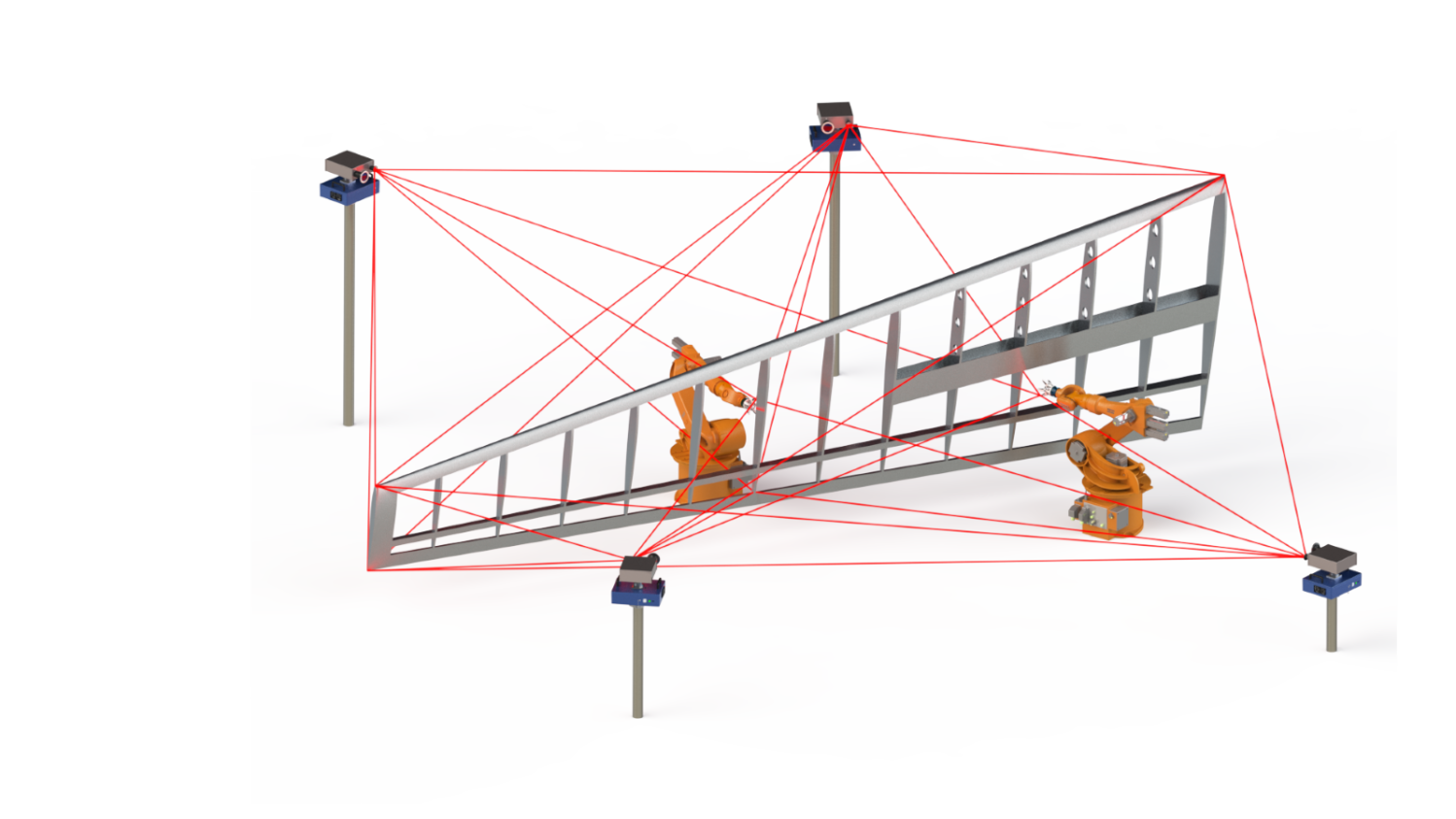

The system combines the best of both existing laser trackers measurement and photogrammetry systems, measuring multiple targets simultaneously at the highest accuracy. It is unique technology comprising hardware and software that provides digitally traceable coordinate measurements - with known uncertainty at the time of use. It works in a similar way to GPS but on a smaller scale, using lasers and in-built quantum frequency standards technology in factories.

The system’s additional novel features include self-calibration, systematic error correction, and real-time performance indicators; while traceability at the point of measurement removes the need for costly downtimes and recalibrations. These additional, rigorous quality metrics are particularly beneficial in highly regulated industries such as aerospace. For example, NPL’s new coordinate measurement system could reduce wing manufacture measurement processing time by up to 30%, which could help increase the production of planes for a manufacturer from a current rate of 60 per month to 80 per month. That’s 240 additional planes produced in one year.

This type of impact means that this new system will transform manufacturing metrology to an essential, value-adding process which drives manufacturing of the future.

A market opportunity study funded by an Explore grant from the Government Office for Technology Transfer (GOTT) demonstrates from both a top-down and bottom-up approach that there’s a £100m plus market opportunity for high-accuracy industrial coordinate measurement systems.

Our ambition is to get this innovative technology into the hands of UK manufacturers, so that they can increase their productivity and competitiveness. NPL holds three patent families (WO2013144648, WO2013144649 and WO2015198044) granted in four regions (Europe, US, China, Japan) for the underpinning technology in NPL’s new coordinate measurement system. Commercialisation is expected to be through a spin-out or JV company, or through licensing the technology. We are initially targeting the aerospace industry but this technology is also suitable for industrial robotics and robotic calibration, and the healthcare delivery markets too. NPL is actively seeking further collaborators and commercialisation funding as part of this journey.

For more information, please contact us.

35 years of experience in developing and licensing successful commercial dimensional metrology instrumentation that is used globally.

15 years of experience developing novel instrumentation for astrophysics and space instrumentation clinical practitioners.

10 years of new product delivery experience, team formation, and delivery of multimillion pound services. 40 years of international metrology industry experience.

Our research and measurement solutions support innovation and product development. We work with companies to deliver business advantage and commercial success.

Contact our Customer Services team on +44 20 8943 7070