X-ray computed tomography (XCT) uses X-rays to create detailed images of structures inside a body, including internal organs, blood vessels and bones. Software can create 3D models from patient XCT scans which can be manipulated and measured as part of diagnostic processes. This is particularly useful for investigating hip joints or other parts of the body. In order to be a useful resource for medical decision-making, the 3D model dimensions must be sufficiently accurate to, for example, assess whether an implant will fit correctly to a patient’s anatomy and for the medical team to have confidence in the measurements.

Synopsys has developed Simpleware, a 3D image processing software, to visualize, quantify and export models from image data (such as MRI, XCT and FIB-SEM). They were keen to gain CE-marking of their software so that it could be used for medical applications. This meant they needed to know the accuracy and uncertainty of virtual dimensional measurements made between points on the 3D models.

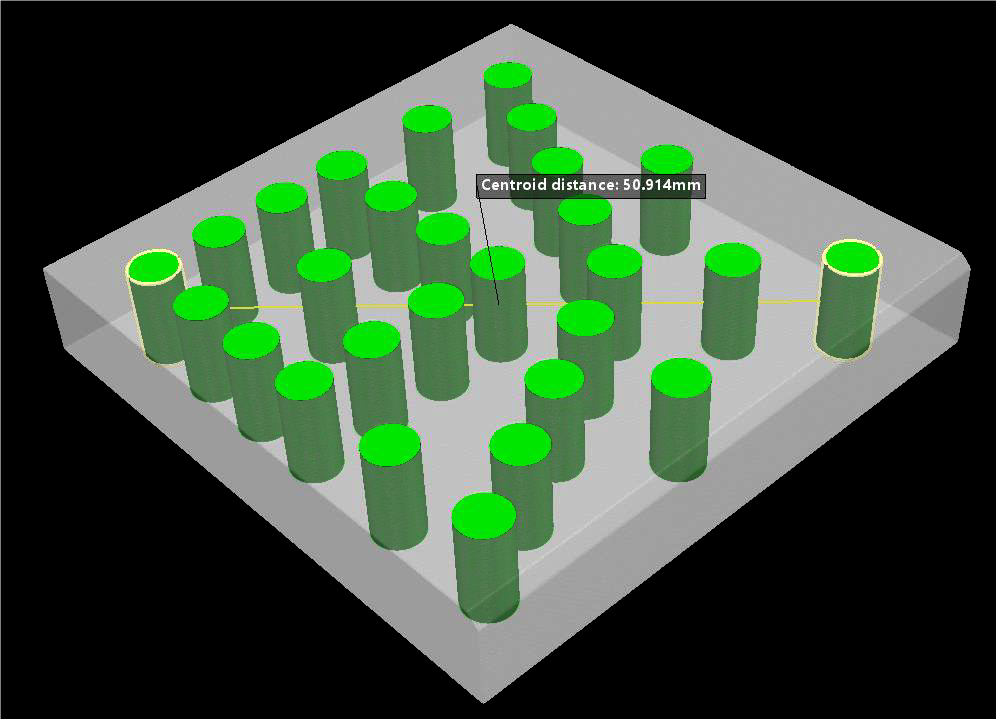

Synopsys approached NPL to help them the find the best way to assess the uncertainty of their virtual measurements. NPL advised that a real artefact was required so that actual measurements could be compared with the virtual measurements. An aluminium plate was machined so that it had a series of holes, which would be reference points for measurements. A high accuracy traceable co-ordinate-measuring system (CMS) was used by NPL to take a series of dimensional measurements on the aluminium plate.

The plate was then CT scanned by NPL and the data was imported into Simpleware software to create a 3D image. Virtual measurements were then taken using the software and compared to the CAD and the calibration from the CMS, respectively. The agreement was very good in both cases and the mean average difference in hole-to-hole measurements was 1.4 µm, which represents 2.89 % of voxel edge length (the 3D virtual distance). The accuracy of the virtual measurement is significantly higher than that required by the medical profession. The good agreement between the virtual and experimental results gives Synopsys confidence that the measurements taken from the 3D digital model, even when rotated or differentiated, can be used by the medical profession to help establish the required treatment and/or bespoke prosthetics. The digital model may be employed, for example, to generate an artificial implant design of a specific shape and dimensions to suit a patient’s anatomy.

The close agreement of the virtual and actual measurements, within the stated measurement uncertainty, means that Synopsys was able to get the Simpleware software CE-marked. This means that it can be used by medical device manufacturers and hospitals, and that they can be confident in using this software to make measurements.

This is an excellent example of using ‘real’ measurements on artefacts to underpin virtual measurements, which in turn builds confidence in the digital equipment and software. Validation of the digital measurements is an important stage in bringing new technology to the medical marketplace and encouraging new ways of working.

Working with NPL was a great partnership, as we were able to validate our measurement tools and approach new applications in the medical market with confidence. The CE-marking for our software helps us to reach customers in the healthcare market, with the accuracy of our measurements being very important to our offering.

Dr Jessica James, Business Process Analyst - Synopsys Simpleware

The Simpleware product group at Synopsys develops software for the conversion of 3D scan data (including MRI, CT and micro-CT) into high quality design, simulation and 3D printing models. Simpleware software is used in fields such as the life sciences, materials science, industrial reverse engineering, NDE, and oil and gas. Easy-to-learn and use, the software offers a robust bridge between the latest imaging technologies and multiple design and simulation applications.