Gauge blocks are one of the most popular length standards in use throughout the world, providing traceability to the SI metre. The NPL designed gauge block interferometers, sold commercially through Hexagon Metrology UK, which are used worldwide for the highest accuracy calibration of gauge blocks and similar engineering artefact standards.

Qatar became an Associate State of the General Conference on Weights and Measures on 10 March 2016 and is a Signatory of the CIPM Mutual Recognition Arrangement. The Qatar Armed Forces Calibration Centre (QAFCC) has responsibility for gauge block calibration and is taking part in inter-laboratory comparisons in preparation for issuing Calibration and Measurement Capability (CMC) statements for international equivalence of measurement standards. Many of the leading National Metrology laboratories around the world use the NPL gauge block interferometer to offer calibration services for gauge blocks and their CMCs are based around the capabilities of this instrument. Without a gauge block interferometer, gauge block calibrations must be referred to higher level gauge block master standards, often calibrated overseas. For a laboratory to operate as the highest authority for gauge block calibrations in a country, some form of interferometer is necessary to provide the link to the SI metre.

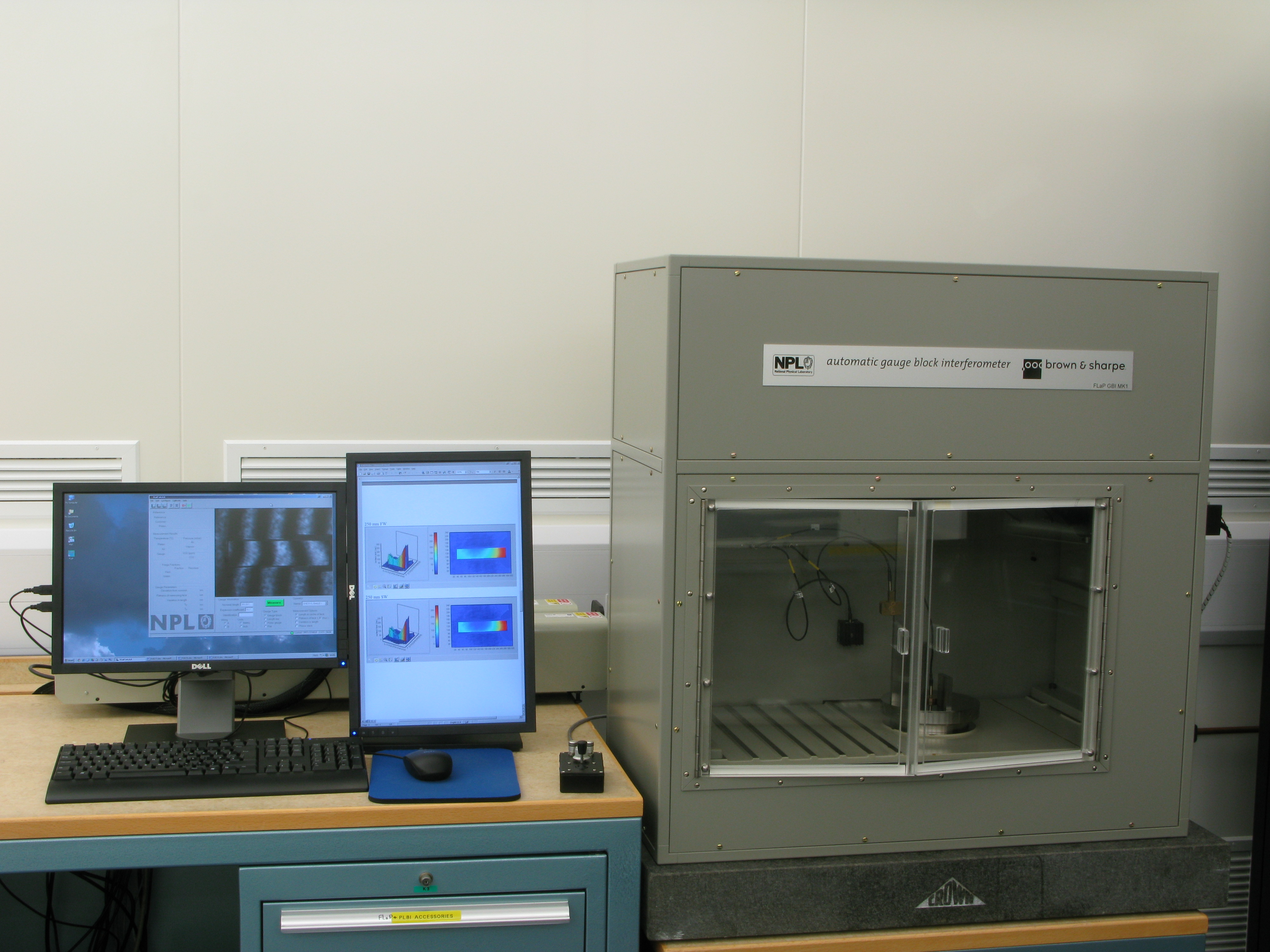

Following installation of the interferometer by Hexagon Metrology, Andrew Lewis from NPL's Dimensional Measurement group travelled to QAFCC to deliver training in the calibration of gauge blocks by interferometry.

.jpg?width=400&height=289)

The NPL gauge block interferometer was designed and licensed to Hexagon Metrology nearly 30 years ago and several iterations and variations of the basic design were produced. The latest version of the instrument used a phase-stepping technique to measure the surface topography of the gauge block, as well as a dual laser system to determine the absolute length. Uncertainties of around 20 to 30 nanometres can be achieved on gauge blocks up to 100 millimetres in length.

The C++ instrument control software, developed at NPL, is also sold through Hexagon Metrology, and stabilised lasers used in the interferometers are manufactured by Hexagon under NPL licence. Instruments and lasers based on NPL designs have been sold to 28 different countries worldwide, with typical customers including National Measurement Institutes, accredited laboratories and high technology laboratories and organisations.

QAFCC now operate the interferometer and can deliver gauge block calibrations at the highest accuracy level. This enables them to prepare CMCs for international review and when accepted, their measurement services for gauge blocks will be accepted internationally.