3 minute read

We have recently collaborated with the Hydrogen Capability Network (HCN) at the Aerospace Technology Institute (ATI), to complete a series of visits to European and American laboratories with established capability for testing materials in cryogenic and hydrogen environments.

Through the visits we were aiming to host joint dialogues with organisations that have expert knowledge on materials testing in cryogenic environments, while identifying key capability and research programmes that would support the acceleration of materials assurance for hydrogen applications. We also hoped to identify potential opportunities for researcher exchange and bilateral training.The European leg of the visits took place in December 2023 and included CERN’s Mechanical Measurements Laboratory and workshop, as well as CryoMak, the Cryogenic Materials Test facility which is part of Karlsruhe Institute of Technology (KIT). Both laboratories are greatly involved in the International Thermonuclear Experimental Reactor (ITER) megaproject where cryogenic testing is required for characterising the superconducting materials used for the coils of the fusion reactor. Consequently, a wide range of mechanical and thermo-physical characterisation techniques are available as well as a wealth of expertise.

Through the visits we were aiming to host joint dialogues with organisations that have expert knowledge on materials testing in cryogenic environments, while identifying key capability and research programmes that would support the acceleration of materials assurance for hydrogen applications. We also hoped to identify potential opportunities for researcher exchange and bilateral training.The European leg of the visits took place in December 2023 and included CERN’s Mechanical Measurements Laboratory and workshop, as well as CryoMak, the Cryogenic Materials Test facility which is part of Karlsruhe Institute of Technology (KIT). Both laboratories are greatly involved in the International Thermonuclear Experimental Reactor (ITER) megaproject where cryogenic testing is required for characterising the superconducting materials used for the coils of the fusion reactor. Consequently, a wide range of mechanical and thermo-physical characterisation techniques are available as well as a wealth of expertise.

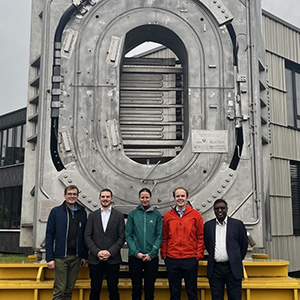

Caption: Group photo after the visit at CryoMak (Karlsruhe, Germany), in front of an ITER fusion reactor coil segment.

For the American segment of the fact-finding mission, the team put together an itinerary for visiting six laboratories in the space of two weeks in February 2024. The laboratories on the tour had a suite of capabilities including cryogenic testing of materials and testing within hydrogen environments, gaseous and/or liquid which is key in supporting the use of advanced materials in hydrogen applications.

The first stop was the Washington State University HYPER laboratory, which is one of the few cryogenic hydrogen research centres in the US academic ecosystem. We spent a full day in the laboratory and were treated to a series of demonstrations that highlighted the lab’s capability, ranging from mechanical tests to a custom-built mobile liquid hydrogen generation unit.

On the second stop, we headed to the Pacific Northwest National Laboratory where the hosts showcased their capabilities in mechanical and thermophysical materials property measurements at cryogenic temperatures using nitrogen and helium, as well as in high-pressure gaseous hydrogen environments.Next on the list was the Sandia National Laboratories (SNL) in Livermore. The focus of the visit was the Hydrogen Effects on Materials laboratory, where SNL’s scientists investigate fatigue crack growth behaviour under high-pressure gaseous hydrogen conditions for energy and transport applications.

On the second stop, we headed to the Pacific Northwest National Laboratory where the hosts showcased their capabilities in mechanical and thermophysical materials property measurements at cryogenic temperatures using nitrogen and helium, as well as in high-pressure gaseous hydrogen environments.Next on the list was the Sandia National Laboratories (SNL) in Livermore. The focus of the visit was the Hydrogen Effects on Materials laboratory, where SNL’s scientists investigate fatigue crack growth behaviour under high-pressure gaseous hydrogen conditions for energy and transport applications.

.jpg.aspx) Caption: The NPL/HCN team joined by the WSU graduates at the HYPER laboratory.

Caption: The NPL/HCN team joined by the WSU graduates at the HYPER laboratory.

To kick off our second week, we headed southeast and spent a day between the National High Magnetic Field Laboratory (NHMFL) and the Florida State University High-Performance Materials Institute (HPMI). NHMFL is the home of some of the world’s strongest magnets. The electro-mechanical test laboratory has extensive capabilities for mechanical, thermal and electrical characterisation of advanced materials and superconductive wires at cryogenic temperatures down to 4.2K.

Caption:Group photo of the team with some of the hosts outside the National High Magnetic Field Laboratory

.jpg.aspx) The last two stops were dedicated to two of the largest NASA field centres. First, the NASA Marshall Space Flight Centre (MSFC), located within the Redstone Arsenal in Huntsville, Alabama. We were shown around the materials test laboratory and had insightful discussions on measuring cryogenic performance on space-grade insulating foams and thermal insulation systems. The visit concluded at the hydrogen test facility where there is a unique capability to test materials in high-pressure gaseous and liquid hydrogen environments.

The last two stops were dedicated to two of the largest NASA field centres. First, the NASA Marshall Space Flight Centre (MSFC), located within the Redstone Arsenal in Huntsville, Alabama. We were shown around the materials test laboratory and had insightful discussions on measuring cryogenic performance on space-grade insulating foams and thermal insulation systems. The visit concluded at the hydrogen test facility where there is a unique capability to test materials in high-pressure gaseous and liquid hydrogen environments.

Caption:Arriving at the Sandia National Laboratories facility in Livermore, CA.

Finally, the trip concluded at NASA Kennedy Space Centre (KSC). We went to the Cryogenics Test Laboratory (CTL) where extensive research around thermal insulation and protection systems has been done for over 20 years, ever since the lab’s formation in support of the Space Shuttle programme. The highlight of the day was undoubtedly the visit to the legendary Launch Complex 39B, home to the largest liquid hydrogen tanks in the world.

Finally, the trip concluded at NASA Kennedy Space Centre (KSC). We went to the Cryogenics Test Laboratory (CTL) where extensive research around thermal insulation and protection systems has been done for over 20 years, ever since the lab’s formation in support of the Space Shuttle programme. The highlight of the day was undoubtedly the visit to the legendary Launch Complex 39B, home to the largest liquid hydrogen tanks in the world.

Overall, the two fact-finding missions have been very successful, accumulating a wealth of expertise and knowledge around cryogenic and hydrogen testing of advanced materials, strengthening the ties with the scientific community. We’re currently working with the team at the ATI on capturing the capabilities and opportunities in the international landscape on an open-access report.

Caption: The world’s largest liquid hydrogen tank, located at NASA Kennedy Space Centre.

NPL

- Nassos Spetsieris

- Stefanos Giannis

- Michael Gower

- Petra Mildeova

HCN

Funding was received from the Department of Science, Innovation and Technology (DSIT) National Measurement System Programme and GRI Tactical Fund (Open Call 4), and the Department of Business and Trade (DBT) Hydrogen Capability Network.

Find out more about NPL’s work in advanced engineering materials

Find out more about advanced engineering materials

18 Mar 2024